-

Medical journals

- Career

OPTIMIZATION OF ZIRCONIA INKS TO FABRICATE 3D POROUS SCAFFOLDS BY ROBOCASTING

Authors: Daniela Brazete; Ana S. Neto; José M. F. Ferreira

Published in: Lékař a technika - Clinician and Technology No. 1, 2019, 49, 5-10

Category:

Overview

High-performance bioceramics such as zirconia, alumina, and their composites, are attractive materials for the fabrication of load-bearing bone implants because of their outstanding mechanical properties, biocompatibility, corrosion resistance, and aesthetic quality. A suitable level of porosity and pore sizes with a few hundred microns are required for a good bone integration of the scaffolds. This requirement can be achieved through additive manufacturing, like robocasting. For this purpose, the optimization of colloidal inks is one of paramount importance as the rheological properties of the inks determine the quality of the three-dimensional structures. This target has not been satisfactorily accomplished in previous research works. The present study aims at closing this gap by carrying out a systematic investigation about the influence of the most important parameters that determine the printing ability of zirconia inks. The dispersing ability of the zirconia powder was studied in order to maximize the solids loading while keeping a high degree of homogeneity of the starting suspensions. The viscoelastic properties of the suspensions were then altered by adding suitable doses of a coagulating agent to obtain easily extrudable pastes for the robocasting process. The green samples were dried and sintered at the heating rate of 1 ºC/min up to 600 ºC, an holding at this temperature for 1 h, followed by an heating rate of 5 ºC/min up to 1350 ºC and holding for 1 h at this temperature, and then cooling down to room temperature. Zirconia inks with high fraction of solids (48 vol%) could be successfully prepared. The extruded cylinders exhibited an excellent shape retention in scaffolds with different macropore sizes (200, 300, 400 and 500 mm).

Keywords:

zirconia ink – 3D porous scaffolds – suspensions – robocasting

Introduction

With aging of population, musculoskeletal diseases affect an increasing number of patients, stimulating the search for new treatments and materials to facilitate bone repair, replacement or regeneration [1, 2]. Every day, biomaterials are used to improve human health and the quality of life of thousands people. They replace or repair different tissues or organs damaged by disease or trauma and cover a wide spectrum of materials like metals, ceramics, glasses, polymers and composites [3]. Ceramics play key roles in orthopedics, and different types of ceramics might be targeted depending on the specific clinical application [4]. Calcium phosphate bioceramics show very good biocompatibility as well as osteoconductive and osteoinductive capabilities. They exhibit good bone regenerating capacity are good choices for filling small bone defects in non-load parts of the skeleton [5–7]. Porous 3D scaffolds are often needed for regeneration of large bone defects. Resorb-able scaffolds can guide bone cells growth, proliferation and differentiation and act as a temporary templates, being gradually degraded and integrated in the newly formed bone [8, 9]. In terms of architecture, the ideal scaffold must exhibit interconnected network of pores with suitable sizes for allowing diffusion and cell migration, and sufficient porosity fraction to facilitate cell ingrowth without weakening too much the mechani-cal properties [10].

Various conventional methods like, coral structures [11], emulsions [12] and freeze gelation [13] have been developed so far for the manufacture of porous 3D structures. However, most of these techniques do not allow building scaffolds with suitable characteristics, including controlled internal pore sizes and pore frac-tions. These disadvantages can be overcome by using solid freeform fabrication (SFF) techniques [14], like robocasting [15–18], which is based on the extrusion of a concentrated suspension, called ink or paste. This technique allows processing 3D scaffolds with straight channels, creating open porosities in x, y, and z direc-tions and has been widely used for processing ceramics [19, 20]. Irrespective of the selected technique, the easiness of processing strongly depends on several pa-rameters related to the starting powder, likely particle size, particle size distribution that influence its packing ability. Moreover, the ink should be able to accommo-date high particle loading [18, 21, 22] for enable a good dimensional control over the entire process and adequate final mechanical properties. Unfortunately, the mechan-ical properties of resorbable materials are relatively low, especially when porous structures (to allow bone ingrowth) are intended. Even in bulk forms, the mechan-ical properties of calcium phosphates are not satisfactory to allow them being selected for load bearing appli-cations. These limitations force researchers to look for better alternatives, even sacrificing the bioactive features. Yttrium partially stabilized tetragonal zirconia polycrystalline material (zirconia) is an attractive material that copes with this stringent requirement. It was firstly used in orthopedic surgery as hip joint prosthesis [23]. Since then, zirconia-based materials have been widely used in diverse dental implants [24] and load bearing orthopedic applications [25]. The interest in the use of zirconia as biomaterial for orthopedics applications comes from its high mechani-cal strength, high flexural strength and suitable Young’s modulus, low susceptibility to plaque formation, out-standing biocompatibility in vivo, good chemical stability and low wear cost [3, 4, 24, 26].

The fabrication of porous zirconia scaffolds by robocasting has already been attempted in a limited number of studies [27–29]. But the reported achieve-ments are still far from being satisfactory. In 2015, Li et al. [27] used a water based ZrO2 ink with a solid loading of 70 wt% to process 3D structures. However, this solid content (corresponding to ~28 vol%), is relatively low for conferring to inks suitable viscoelastic properties for printing. Peng et al. [29] produced macro porous scaf-folds by robocasting from inks of 3 zirconia powders. They report higher solid loadings (up to 38 vol%), but the elastic moduli of the inks were not enough high to allow a good shape retention. Still a higher solid loading (47 vol%) was reported in another study by Liao et al. [28]. But the selection of the processing additives was not the most appropriate to confer high enough elastic moduli to the inks for shape retention. The scarce number of literature reports about printing zirconia scaffolds by robocasting, and the poor degree of rheo-logical control of the inks demand for new studies towards making further progresses in this field.

Besides solid loading, the types of processing additives need to be judiciously selected, and their concentrations have to be suitably adjusted for an opti-mal processing. For properly extruding continuous fila-ments, the inks must exhibit shear thinning rheological behavior within the viscosity range of 10–100 Pa×s to flow easily through fine diameter nozzles under the applied force. The elastic modulus (G’) of the inks need to be relatively high (preferentially within 1-10 MPa) over an extended linear viscoelastic plateau up to shear yield stress >200 Pa. These conditions will allow the extruded filaments to support their own weight during

the layer by layer deposition process. All the above mentioned parameters affect the quality of green body and consequent mechanical properties and reliability of the 3D printed scaffolds [18, 21, 22, 30].The main aim of this work is developing a high concentrated colloidal ink with viscoelastic properties suitable for the reliable fabrication of 3D porous zirconia scaffolds with different pore sizes by robo-casting.

Materials and Methods

Zirconia ink development

An yttrium partially stabilized tetragonal zirconia powder (3YS, TOSOH, Japan) with density = 6.05 g×cm−3 and an isoelectric point (IEP) at around pH 4, was used to prepare the ink for robocasting. Initially, aqueous suspensions with 45 vol% solids were prepared in the presence of different concentrations (0.3, 0.5 and 0.8 wt%) of an alkali free anionic dispersant, (Dolapix CE 64, Zschimmer & Schwarz, Germany). To prevent aggregation and to have a homogeneous dispersion, the zirconia slurries were left overnight under stirring before being tested.

Particle size measurements were evaluated using a particle size analyzer (COULTER LS230, UK) with Fraunhofer optical model.

The rheological behavior of the as obtained suspen-sions was tested in order to select the most suitable added amount of dispersant. After selecting the optimal content of dispersant, the solid volume fractions were increased to find out the maximum achievable solids loading. The selection criterion at this stage is the lowest relative viscosity level enabled by the optimal amount of dispersant. However, the intrinsic viscosity of the suspensions needs to be increased to minimize particle segregation under shear. Therefore, the next step of the optimization process involves adding a suitable binder/viscosifying agent. With this purpose, a suitable amount (2 wt% relative to dry mass of solids) of hydroxypropyl methylcellulose (HPMC) was added to the optimal formulation. Finally, the internal structure and the elasticity of the system needs be increased to allow shape retention of the extruded filaments. This target was achieved by testing different added amounts (0.01-0.03 wt%) of polyethylenimine (PEI, 50% w/v in water, Sigma-Aldrich), a cationic additive that promotes the collapse of the electrical double layer and the steric hindrance exerted by the adsorbed anionic polyelectro-lyte chains in the required extent.

All the prepared suspensions and pastes were placed in a planetary centrifugal mixer (ARE-250, Thinky Corp., Tokyo, Japan) for a few minutes in order to improve their degrees of homogeneity before being tested for rheological properties or used for scaffolds fabrication.

Rheological characterization of the inks

The rheology tests were performed on a Kinexus Pro + Rheometer, which were conducted at 25 ºC in a closed environment to avoid liquid evaporation during the tests. For this, a Kinexus hood solvent trap and cover were used. The flow curves were obtained in rotational mode, using a plate-cone sensor (4º / 40 mm) with a gap of 150 mm. The viscoelastic properties were evaluated in oscillatory mode using a parallel-plate sensor with a gap of 1 mm under a constant frequency of 1 Hz.

Scaffold fabrication and characterization

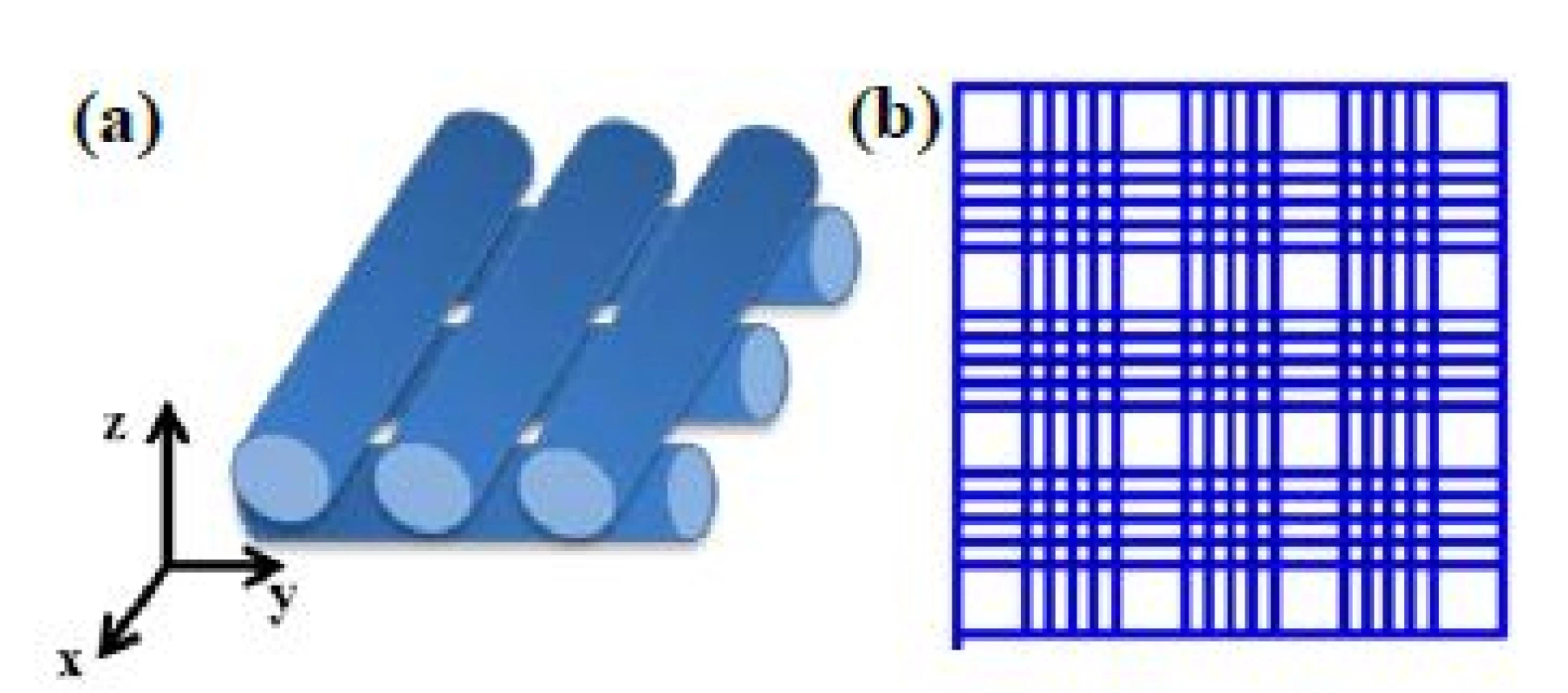

The zirconia scaffolds were printed using a robotic deposition device (3-D Inks, Stillwater, OK). The paste under test was placed into a syringe with a nozzle (EFD Inc., East Providence, RI) having a diameter of 410 μm and extruded at a printing speed of 10 mm·s-1. The filling of the syringe has been done carefully to avoid the formation of air bubbles, which can compromise the mechanical properties of the scaffold. The deposition occurs into a paraffin oil bath to prevent the drying of the parts after printing, and is controlled by the computer through a robotic system. The injector is moved following the CAD models designed by Robocad 4.1.12 software. An example of scaffold models is shown in Fig. 1. In this case, each structure with a total of 12 layers consisted of 9 scaffolds each one with 3×3×3 mm and with pore sizes of 200, 300, 400 and 500 mm.

1. 1: (a) Schematic structure of the pile wood type deposition of filaments in each individual scaffold; (b) CAD model of the general scaffolds assembling.

Samples were removed from the oil and dried at room temperature during 24 h. They were sintered at the heating rate of 1 ºC·min-1 up to 600 ºC, holding at this temperature for 1 h, followed by a heating rate of 5 ºC·min-1 up to 1350 ºC and holding for 1 h at this temperature, and then cooling down to room tempera-ture and observed through an optical loupe.

Results and discussion

Zirconia powder characterization

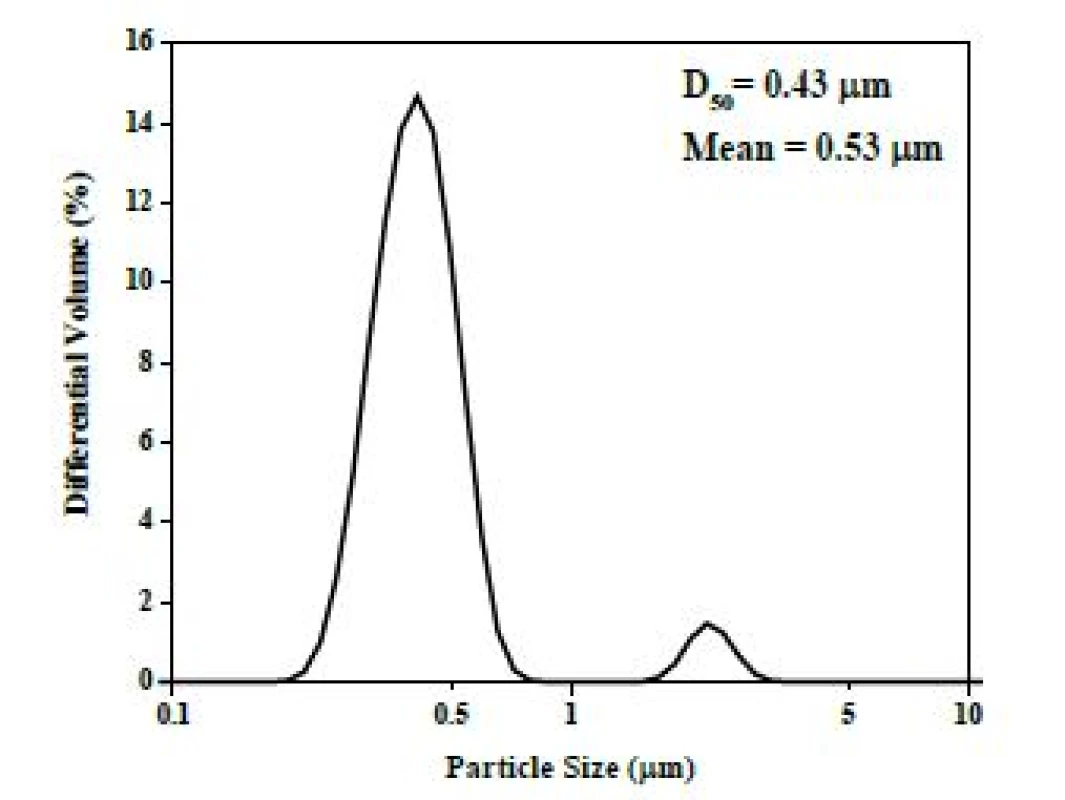

The particle size distribution (PSD) of the zirconia powder is one of the most important factors for obtaining inks with good capacity to be extruded. Fig. 2 shows that the PSD of starting powder is relatively narrow and consists of two particles populations: (i) a coarser one of low intensity population centered at ~1.46 µm, probably to an insufficient destruction of particle agglomerates; (ii) and a main population of primary particles centered at about (0.41 µm). Therefore, is not surprising that the mode of the main population almost coincides with the D50 value (0.43 µm) of the overall PSD. These results confirm that the powder is fine enough for being used without further milling.

2. Particle size distribution of zirconia powder.

Although a wide PSD is often considered beneficial for enhancing particle packing as it allows the incorporation of the finer particles in the interstitial spaces among the coarser ones [31, 32], a narrow PSD favors the densification behavior upon sintering as the driving force for densification is related to the radii of curvature of the pores in the green microstructure [33]. On the other hand, coarse particles form skeletal structures that tend to hinder densification.

Inks optimization for robocasting

The viscoelastic properties of the slurry should allow for its easy extrusion and for shape retention of the filaments after deposition. The elastic modulus of the paste must be high enough to prevent the collapsing of the filaments to occur in the extensions not supported by the underneath layer and also to support the deposition and weight of the subsequent layers without deformation [22, 34]. The suitable particle size and high concen-tration slurries are essential requirements on the slurry preparation for printing of scaffold by robocasting.

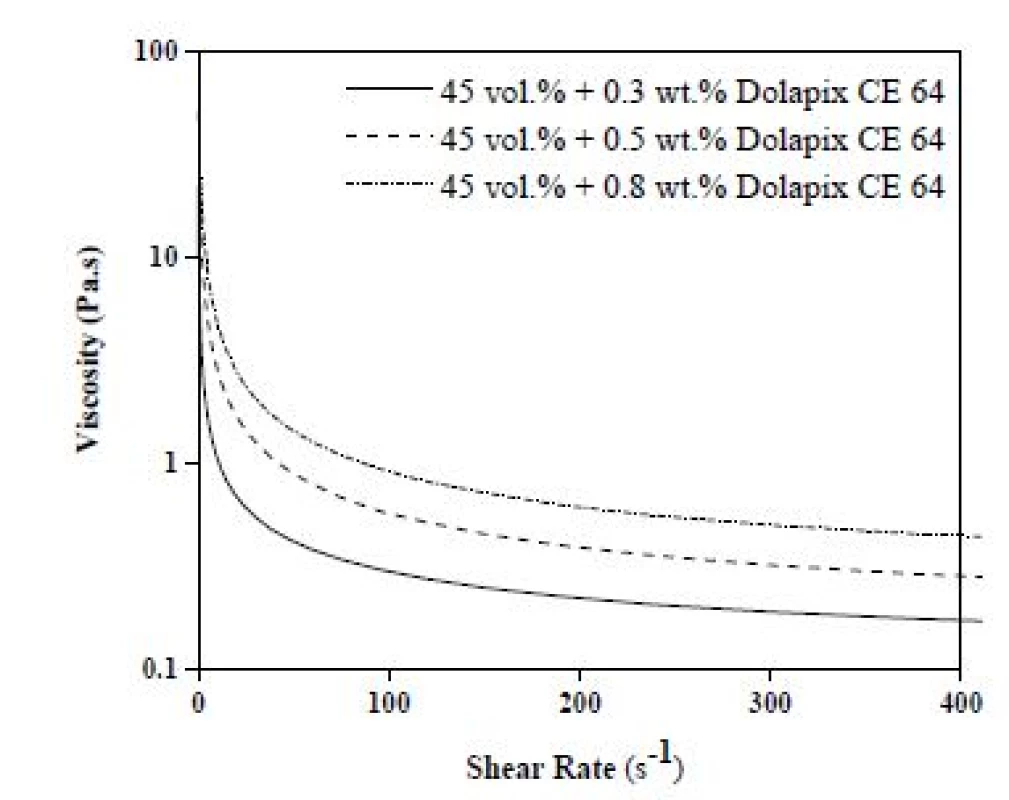

The flow curves of the slurries with 45 vol% solids dispersed with different added amounts of Dolapix CE 64 (0.3, 0.5 and 0.8 wt%) are displayed in Fig. 3.

3. Rheological flow behavior of zirconia suspen-sions with 45 vol% solids in the presence of different amounts (0.3, 0.5 and 0.8 wt%) of Dolapix CE 64.

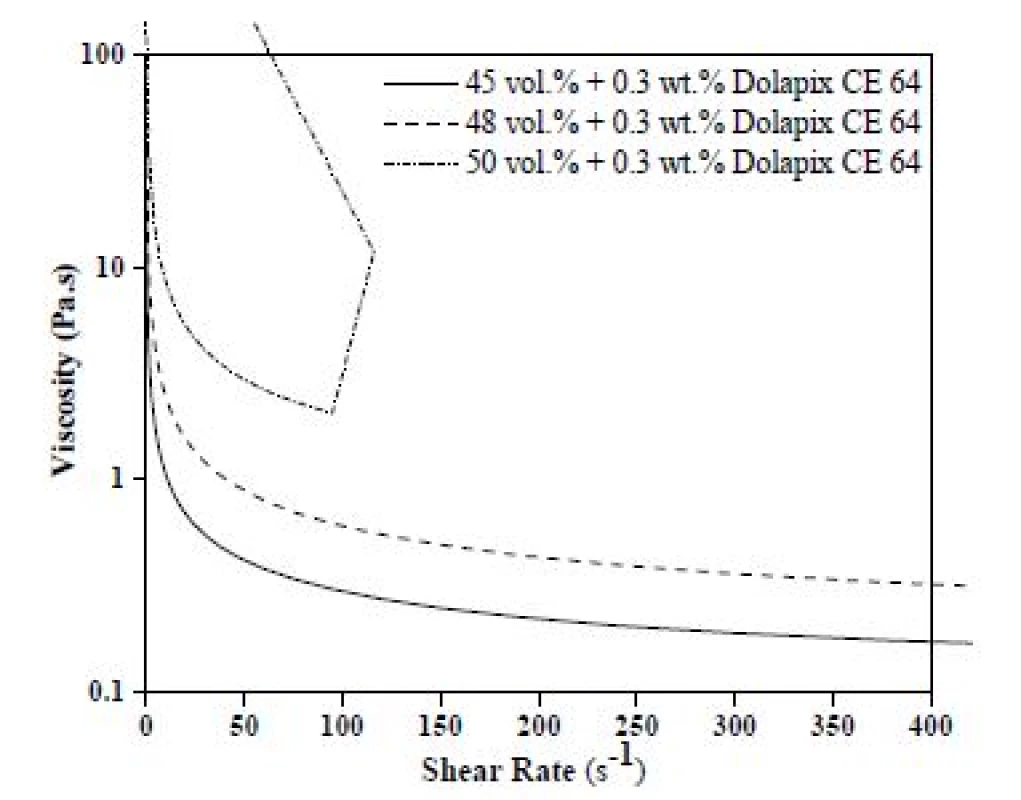

It can be seen that the lower apparent viscosity level was obtained for the lower added amount of dispersant. On the other hand, preliminary dispersion tests using the same powder and the same dispersant revealed that contents of dispersant inferior to 0.3 wt% were not effective [29]. Based on these evidences, this amount of dispersant (0.3 wt%) was chosen as the optimal one. All the suspensions exhibit the desired shear-thinning behavior characteristic of homogeneous and well deagglomerated suspensions. But in order to decrease the shrinkage along the overall process and enhance dimensional control and the processing ability, it is essential to increase the solids concentration in the final suspension while keeping a workable viscosity. The apparent viscosity curves of the slurries containing 45, 48 and 50 vol% solids dispersed with 0.3 wt% Dolapix CE 64 are shown in Fig. 4. It can be seen that the apparent viscosity curves of the 45 and 48 vol% suspensions are smooth and shear-thinning. However, with further increasing the solid loading to 50 vol% the shear-thinning features could only be observed within the lower shear rate range (up to ~90 s-1), suddenly changing to shear-thickening in a first step, and finally restraining the movement of the cone sensor by shear induced flocculation. These are clear evidences that this concentration of solids (50 vol%) is excessive, at least for the degree of particle deagglomeration achieved (Fig. 2). The 48 vol% suspension exhibits a suitable rheological behavior with apparent viscosity decreasing as the shear rate increases within the entire shear rate range tested. Therefore, this solid loading was adopted in the subsequent paste preparation step.

4. Rheological flow behavior of zirconia suspen-sions with different concentrations of solids and 0.3 wt% Dolapix CE 64.

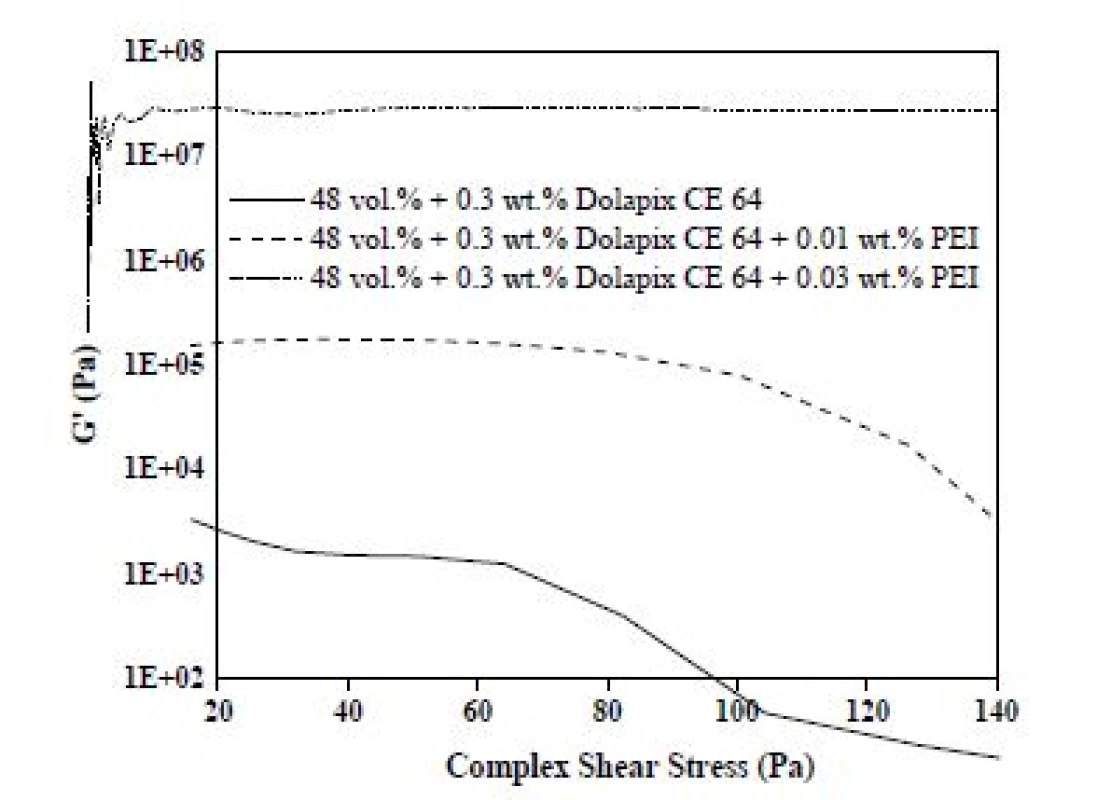

The amount of hydroxypropyl methylcellulose (HPMC) added to the suspension was selected based on the results reported in a previous study [19]. With addition of 2 wt% HPMC there was an increase in viscosity that prevents segregation of particles during printing, maintains the homogeneity and packaging of the filaments particles in the various layers of the scaffolds. Since the viscoelastic properties of the inks need to be appropriately adjusted to ensure good printing and shape retention, the amount of the coagulating agent (PEI) was varied within the limits stated above (0.00, 0.01 and 0.03 wt%). Fig. 5 shows the dynamic mechanical spectra of the tested systems. In the absence of PEI the suspension is too fluid and improper for printing. The elastic features are gradually increased with increasing concentrations of PEI (0.01 and 0.03 wt%). Accordingly, not only the elastic modulus is noticeably increased but also the linear viscoelastic region (LVR) becomes considerably broaden with increasing PEI contents.

5. Effects of the presence of a fixed content of HPMC (2 wt%) and different added amounts of PEI on the viscoelastic properties of the inks assessed under oscillatory amplitude sweep measurement.

For the paste with 0.01 wt% PEI the extent of the LVR is still limited and does not grant proper processing conditions. From these results it is possible to infer that the system with the highest added amount of PEI offers better conditions for shape stability of the extruded filaments. Accordingly, the ink with 0.03 wt% PEI was the formulation chosen for printing scaffolds by robocasting. Since the processing additives (dispersant, viscosifying agent and gelling agent) are added as aqueous solutions, the optimized slurry end up with a solid fraction of 41 vol%, corresponding to 83.5 wt%.

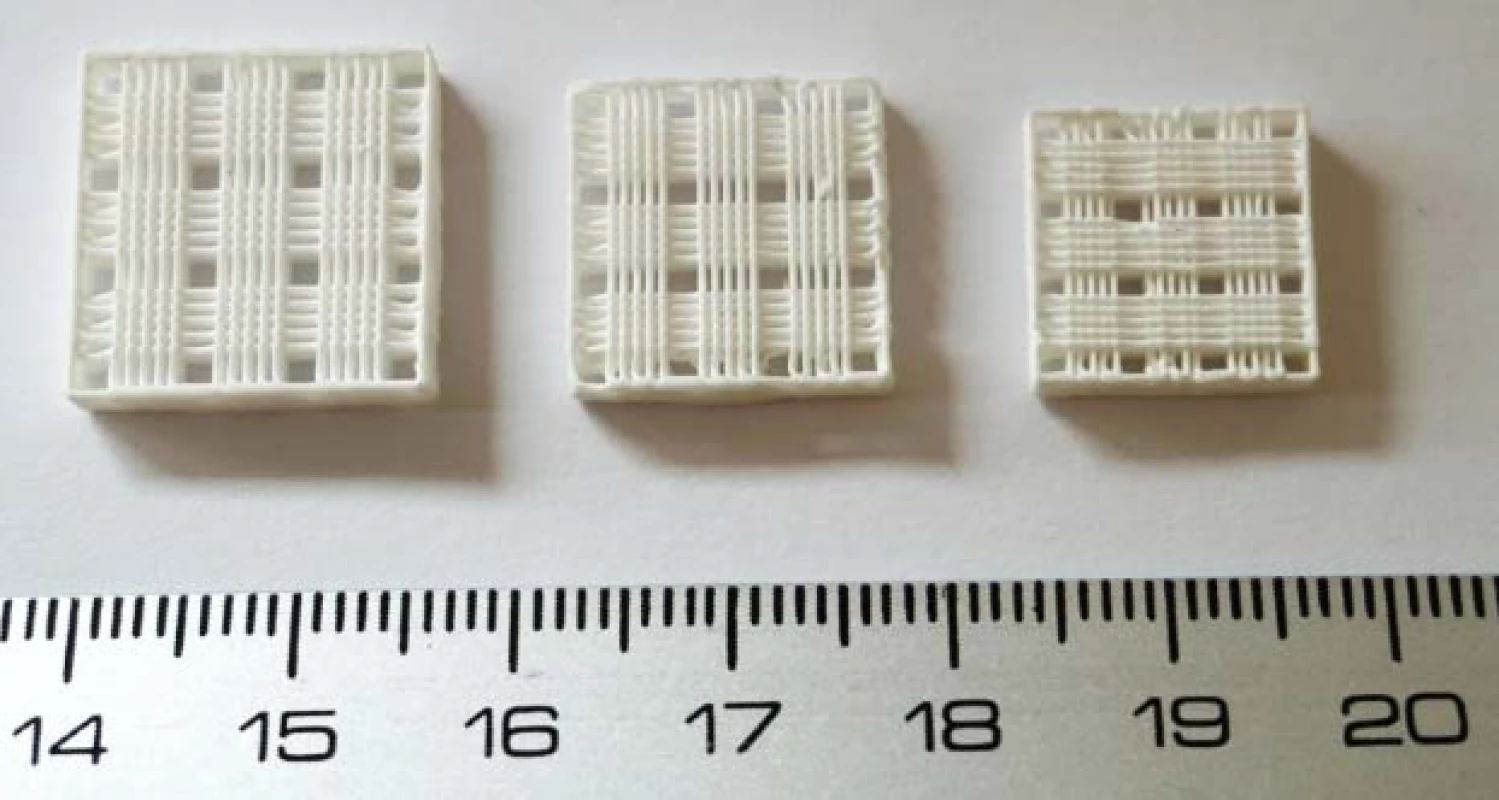

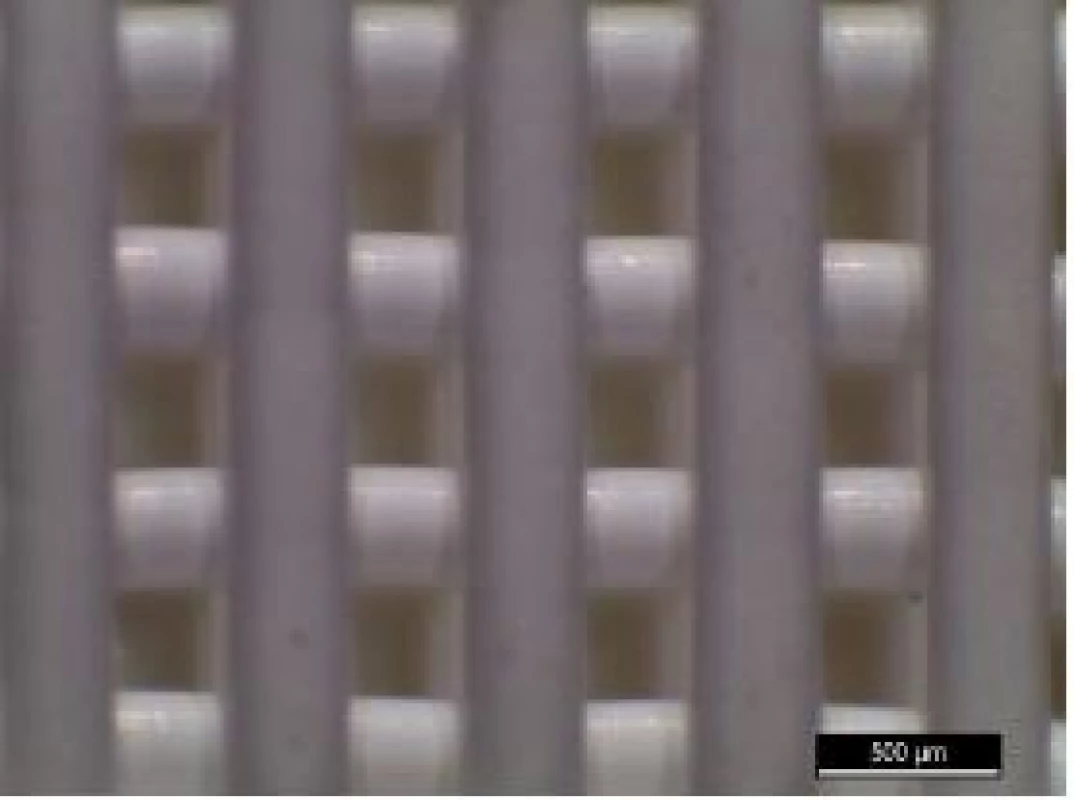

Scaffolds with 300, 400 and 500 mm pore sizes were prepared using the previously optimized ink, a picture of which is shown in Fig. 6. The photograph shows a ZrO2 scaffolds after sintering, which exhibit symmetric shapes. The deposited roods exhibited a cylindrical form and excellent shape retention, as observed in Fig. 7.

6. Zirconia scaffolds with different pore sizes (500, 400 and 300 μm) produced according to the CAD model shown in Fig. 1.

7. Zirconia scaffold with 400 μm pore sizes after sintering at 1350 ºC (35×).

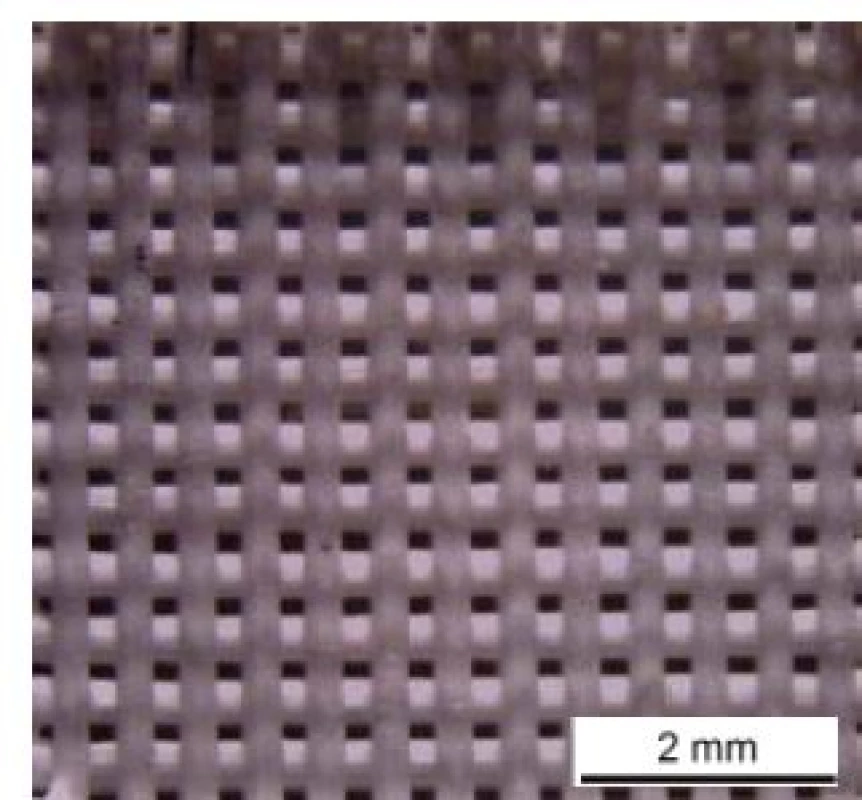

Scaffolds designed with the smallest pore sizes 200 mm could also be easily printed as can be seen in the example shown in Fig. 8. These results demonstrate that the inks prepared in the frame of the present work enjoy of excellent printing capabilities for being used in the fabrication of a variety of porous structures.

8. Zirconia scaffolds designed with the smallest pore sizes (35×).

Conclusion

A zirconia powder with a relatively narrow PSD was successfully used to prepare suitable inks for 3D printing by robocasting. The optimized ink has a high fraction of solids (48 vol%) and exhibits shear thinning behavior, a high elastic modulus, and a very extended linear viscoelastic region that grants shape retention of the extruded filaments. These optimal processing conditions are promising for printing porous structures with excellent shape retention capabilities, going be-yond the realizations previously reported in the literature. These achievements represent a good plat-form for future work aiming at producing mechanically reliable porous scaffolds for load bearing applications.

Acknowledgement

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, POCI-01-0145-FEDER-007679 (FCT Ref. UID /CTM/50011/

2013), University of Aveiro, financed by national funds through the FCT/MEC, Portugal, and when appropriate co-financed by FEDER under the PT2020 Partnership Agreement. Ana S. Neto is grateful to AdvaMTech, the PhD Program on Advanced Materials and Processing for the PhD grant, PD/BD/114132/2015, founded by the Portuguese Foundation for Science and Technology (FCT).José M. F. Ferreira

Department of Materials and Ceramic Engineering

CICECO, University of Aveiro

Campus Santiago, 3810-193 Aveiro, Portugal

E-mail: jmf@ua.pt

Sources

- Nilsson M. Injectable Calcium sulphate and Calcium Phosphate bone substitutes. Department of Orthopaedics. Lund University; 2003.

- Jordan KM, Cooper C. Epidemiology of osteoporosis. Best Pract. Res. Clin. Rheumatol. 2002;16(5):795-806.

- Planell JA, Navarro M. Challenges of bone repair. 2009.

- Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20(1):1-25.

- Dorozhkin SV. Calcium orthophosphates in dentistry. J. Mater. Sci. Mater. Med. 2013;24(6):1335-63.

- Ramesh S, Tan CY, Tolouei R, Amiriyan M, Purbolaksono J, Sopyan I, Teng WD. Sintering behavior of hydroxyapatite prepared from different routes. Mater. Des. 2012;34 : 148-54.

- Dorozhkin S. Calcium Orthophosphates: Applications in Nature, Biology, and Medicine. Taylor & F.; 2012.

- Moroni L, De Wijn JR, Van Blitterswijk CA. Integrating novel technologies to fabricate smart scaffolds. J. Biomater. Sci. Polymer. 2008;19(5):543-72.

- Liu CZ, Czernuszka JT. Development of biodegradable scaffolds for tissue engineering: a perspective on emerging technology. Mater. Sci. Technol. 2007;23(5):379-91.

- Turnbull G, Clarke J, Picard F, Riches P, Jia L, Han F, Li B, Shu W. 3D bioactive composite scaffolds for bone tissue engi-neering. Bioact. Mater. 2018;3(3):278-314.

- Ben-Nissan B. Natural bioceramics: From coral to bone and beyond. Curr. Opin. Solid State Mater. Sci. 2003;7(4–5):283-8.

- Bohner M, Van Lenthe GH, Grünenfelder S, Hirsiger W, Evison R, Müller R. Synthesis and characterization of porous β-tricalcium phosphate blocks. Biomaterials. 2005;26(31):6099-105.

- Soltmann U, Böttcher H, Koch D, Grathwohl G. Freeze gelation: A new option for the production of biological ceramic com-posites (biocers). Mater. Lett. 2003;57(19):2861-5.

- Bose S, Ke D, Sahasrabudhe H, Bandyopadhyay A. Additive manufacturing of biomaterials. Prog. Mater. Sci. 2018;93 : 45-111.

- Marques CF, Perera FH, Marote A, Ferreira S, Vieira SI, Olhero S, Miranda P, Ferreira JM. Biphasic calcium phosphate scaffolds fabricated by direct write assembly: Mechanical, anti-microbial and osteoblastic properties. J. Eur. Ceram. Soc. 2017; 37(1):359-68.

- Eqtesadi S, Motealleh A, Miranda P, Pajares A, Lemos A, Ferreira JM. Robocasting of 45S5 bioactive glass scaffolds for bone tissue engineering. J. Eur. Ceram. Soc. 2014;34(1):107-18.

- Lewis JA. Direct-write assembly of ceramics from colloidal inks. Curr. Opin. Solid State Mater. Sci. 2002;6(12):245-50.

- Michna S, Wu W, Lewis JA. Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds. Biomaterials. 2005;26(28):5632-9.

- Peng E, Zhang D, Ding J. Ceramic Robocasting: Recent Achievements, Potential, and Future Developments. Ceram. Addit. Manuf. 2018;1802404 : 1-14.

- Travitzky N, Bonet A, Dermeik B, Fey T, Filbert-Demut I, Schlier L, Schlordt T, Greil P. Additive Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2014;16(6):729-54.

- Smay JE, Cesarano J, Lewis JA. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir. 2002;18(14): 5429-37.

- Franco J, Hunger P, Launey ME, Tomsia AP, Saiz E. Direct write assembly of calcium phosphate scaffolds using a water-based hydrogel. Acta Biomater. 2010;6(1):218-28.

- Stewart TD, Tipper JL, Insley G, Streicher RM, Ingham E, Fisher J. Severe wear and fracture of zirconia heads against alumina inserts in hip simulator studies with microseparation. J. Arthro-plasty. 2003;18(6):726-34.

- Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent. Mater. 2008;24(3):299-307.

- Aboushelib MN, Shawky R. Osteogenesis ability of CAD/CAM porous zirconia scaffolds enriched with nano-hydroxyapatite particles. Int. J. Implant Dent. 2017;3(21).

- Chevalier J, Gremillard L. Ceramics for medical applications: A picture for the next 20 years. J. Eur. Ceram. Soc. 2009;29(7): 1245-55.

- Li Y, Li L, Li B. Direct write printing of three-dimensional ZrO2 biological scaffolds. Mater. Des. 2015;72 : 16-20.

- Liao J, Chen H, Luo H, Wang X. Direct ink writing of zirconia three-dimensional structures. J. Mater. Chem. C. 2017;5 : 5867-71.

- Peng E, Wei1 X, Garbe U, Yu D, Edouard B, Liu A, Ding J. Robocasting of dense yttria-stabilized zirconia structures. J. Mater. Sci. 2018;53(1):247-73.

- Feilden E, Blanca EG, Giuliani F, Saiz E, Vandeperre L. Robocasting of Structural Ceramic Parts with Hydrogel Inks. J. Eur. Ceram. Soc. 2016;36 : 2525-33.

- Olhero SM, Ferreira JM. Influence of particle size distribution on rheology and particle packing of silica-based suspensions. Powder Technol. 2004;139(1):69-75.

- Kocjan A, Pouchly V, Shen Z. Processing of zirconia nano-ceramics from a coarse powder. J. Eur. Ceram. Soc. 2015;35(4): 1285-95.

- Zocca A, Colombo P, Gomes CM, Günster J. Additive Manu-facturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015;98(7):1983-2001.

- Olhero SM, Lopes E, Ferreira JM. Fabrication of ceramic microneedles – The role of specific interactions between processing additives and the surface of oxide particles in Epoxy Gel Casting. J. Eur. Ceram. Soc. 2016;36(16):4131-40.

Labels

Biomedicine

Article was published inThe Clinician and Technology Journal

2019 Issue 1-

All articles in this issue

- DESIGN, MANUFACTURE AND TESTING OF RABBIT IMPLANTATION STRUCTURES FOR PRECLINICAL EXAMINATIONS

- APPLICATION OF SENSORY SYSTEMS TO MOVE DOGS WITH VISUAL IMPAIRMENT

- COST ANALYSIS OF TWO TYPES OF THE LUMBAR SPINE STABILIZING SURGERY

- CERAMIC ARCHITECTURES AS MODELS FOR 3D PRINTED TISSUE ENGINEERING APPLICATIONS

- OPTIMIZATION OF ZIRCONIA INKS TO FABRICATE 3D POROUS SCAFFOLDS BY ROBOCASTING

- The Clinician and Technology Journal

- Journal archive

- Current issue

- Online only

- About the journal

Most read in this issue- OPTIMIZATION OF ZIRCONIA INKS TO FABRICATE 3D POROUS SCAFFOLDS BY ROBOCASTING

- COST ANALYSIS OF TWO TYPES OF THE LUMBAR SPINE STABILIZING SURGERY

- CERAMIC ARCHITECTURES AS MODELS FOR 3D PRINTED TISSUE ENGINEERING APPLICATIONS

- DESIGN, MANUFACTURE AND TESTING OF RABBIT IMPLANTATION STRUCTURES FOR PRECLINICAL EXAMINATIONS

Login#ADS_BOTTOM_SCRIPTS#Forgotten passwordEnter the email address that you registered with. We will send you instructions on how to set a new password.

- Career