-

Medical journals

- Career

APPLICATION OF SENSORY SYSTEMS TO MOVE DOGS WITH VISUAL IMPAIRMENT

Authors: Jana Klímová; Viktória Krajňáková; Jozef Živčák

Published in: Lékař a technika - Clinician and Technology No. 1, 2019, 49, 16-20

Category:

Overview

This study focuses on the sensory systems application in dog´s movements with visual impairment. The aim of this work was realization and design the production of orthotic instrument for the blind dog because of there has been nothing similar at the market available yet. The work has used non-invasive detection of the animal´s body measure. An instrument has been generated by using CAD software. By help of 3D printer, the virtual model has become real. The product has been cleansed and a system for gripping and for eye protectors has been applied. By studying different types of sensor for application we have decided to choose an ultrasonic position sensor which is harmless for dog´s hearing. A sensor has detected an approaching obstacle by using the Arduino platform. The obtained results and production of this device can be helpful in innovative development of finding new ways in animal´s rehabilitation as well as in rehabilitation of people.

Keywords:

eye diseases of dogs – 3D scanner – 3D printer – position sensors

Introduction

At present, increasing emphasis is being placed on tackling animal health problems, so there is a need to constantly innovate animal-friendly devices. This study focuses on the production of orthotics for a visually impaired dog. New non-invasive procedures are used to determine the exact dimensions of the animal's body. Dog head dimensions were measured using a 3D scanner. The aid was made with customized 3D printers. The ultrasonic sensor has been applied to the helmet in order not only to fill the mechanical protection function. The sensor provides a warning to warn the dog of an obstacle. The suggested alternative is to create a model based on a scan that includes a sensor housing to prevent the sensor from being destroyed and to minimize the dimensions. It is also advisable to take advantage of the use of a gyroscope to ensure correctness of the obstacle signaling. The gyroscope may also be part of an ultrasound sensor. This would prevent the obstacle from being signaled in the case of the inclined head of the dog when it is not necessary. Improving sensory systems brings many benefits to people who are struggling with some kind of disability. Biomedical engineering is increasingly focused on improving the comfort of life, whether for humans or for animals. The aim of the paper was to provide the greatest comfort for the affected dog while also simplifying the life of the owner. [1, 2]

Analysis of sensory devices and systems for dogs with visual impairment

In the last decade, interest in the use of sensory aids has also increased in veterinary practice. One of the greatest benefits is the 3D scanner and imaging techniques. In recent years, veterinarians have been largely concerned with locomotion, movement and stabilization capabilities in animals. Study of the use of sensory systems is an important part of research, as it can provide a new perspective on rehabilitation treatment options for people. [2]

A helper for blind dogs

The only available tool for blind dogs on the market is Halo Blind Dog (Figure 1). Halo Blind Dog is a simple way for the blind dog to gain confidence in the navigation around. If the vision loss is permanent, a device such as Halo Blind Dog can help the dog overcome some of the fear associated with possible hitting his head to objects, furniture or walls, which he is not able to see. [3, 4]

Methodology and preparation of orthotic aid for visually impaired dogs

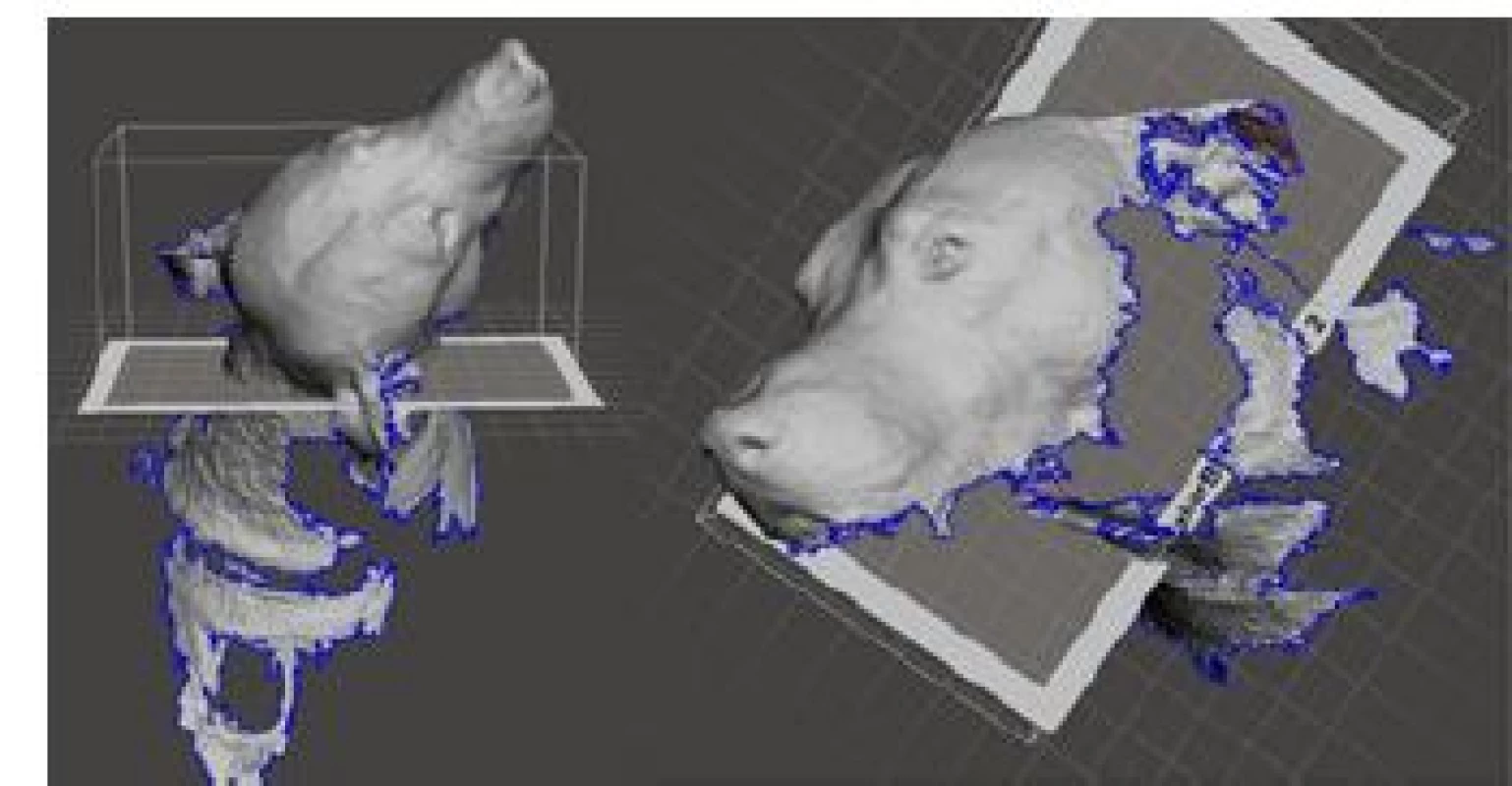

Digitization and modifying data

The aid that was made is for the non-seeing dog Terrier Jack Russell. The dog is 10 years old. The aid serves as a helmet and performs a mechanical protective function because the affected dog is more susceptible to injury. The head of the dog was scanned using a hand-held Artec Eva 3D scanner (Artec Europe, Luxembourg) (Figure 2). Scanning of active animals is very demand-ing due to their constant movement and the subsequent creation of artifacts. Otherwise, this was not the case of this individual, so the subsequent correction in the software is more demanding. After scanning the dog's head, the scan was loaded into the computer and then an STL file was generated that could be edited in the Meshmixer software (Autodesk, Inc., California, USA). [6]

This dog, even though he is blind, is still very likely that he recognize light and darkness. This is the main reason why the model has been adjusted so that the eyes are not covered. Subsequently, the nose was extended and tested immediately on the dog to confirm correct scan dimension. The product accurately copied the surface of the head, so the input data was correct. The tested model was not suitable because it did not cover the entire area of the nose and also the eyes were not protected. The proposed extension had an undesirable effect, and that the surface touched the ground during moving. [6, 7]

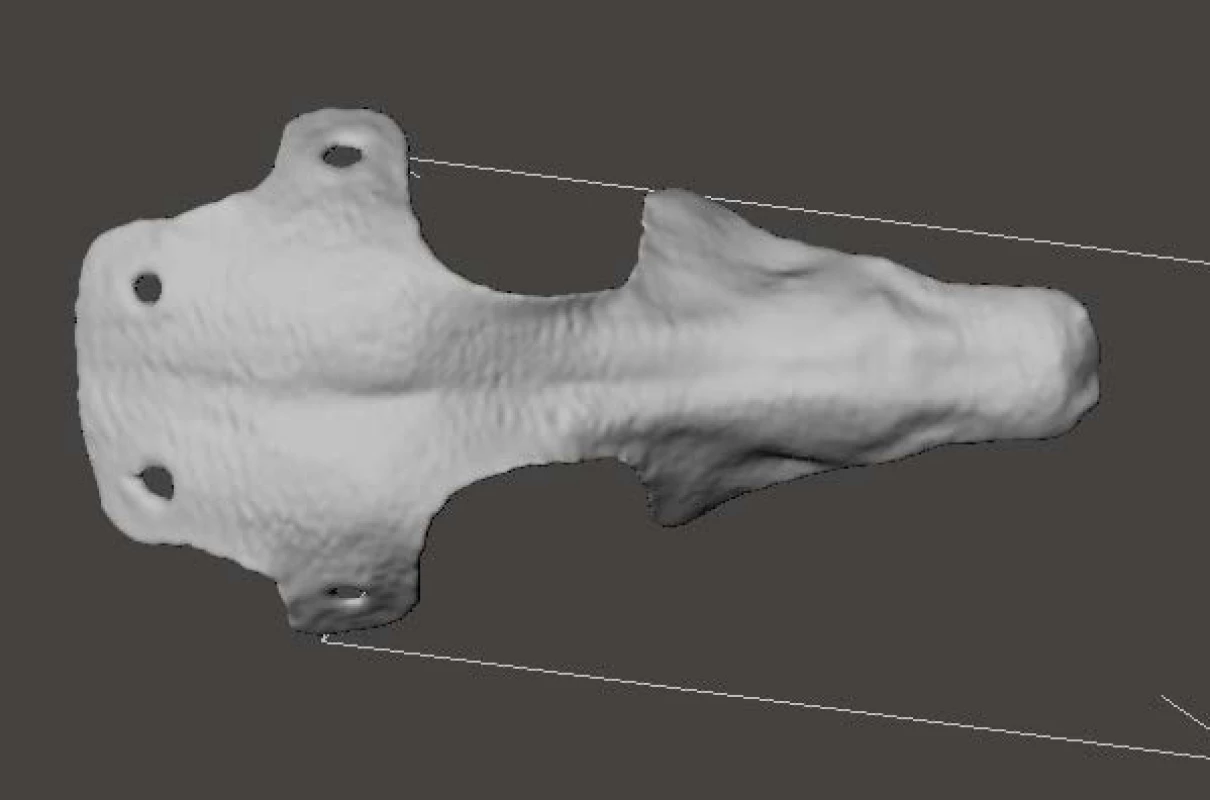

The model was modified by getting wider in the area of the nose, the eyes remaining uncovered and the lenght did not extend beyond the end of the nose. On this model, which is in Figure 3, the headband system has been improved.

3. The final model. Material and production by additive

Material and production by additive manufacturing

It is the technology that makes virtual models real and palpable. This technology makes it possible to create prototypes for production directly from digital data. 3D printing was carried out on the Fortus 450mc printer from Stratasys (Minnesota, USA). This printer has been chosen to select a specific material suitable for such devices, and at the same time it has a high degree of accuracy because it is an industrial printer. The device has been extruded from ASA (acrylonitrile‑styrene acrylate), a high-quality thermoplastic with high resis-tance to UV radiation and weather conditions. It has good mechanical resistance, stiffness, temperature resis-tance and easy processability in 3D printers. A great advantage of this material, especially in tailor-made devices, is its dimensional stability. The device was printed using FDM (Fused Deposition Modeling) technology, which is an additive coating material layer-by-layer. FDM technologies require support structures. The support structure is pressed from the same material as the product with only a different curing time. Finally, the attachment system could be sewed to the helmet and glued goggles from the PET (polyethylene terephthal-ate). Goggles were cut exactly according to the opening dimensions (Figure 4). [8, 9, 10]

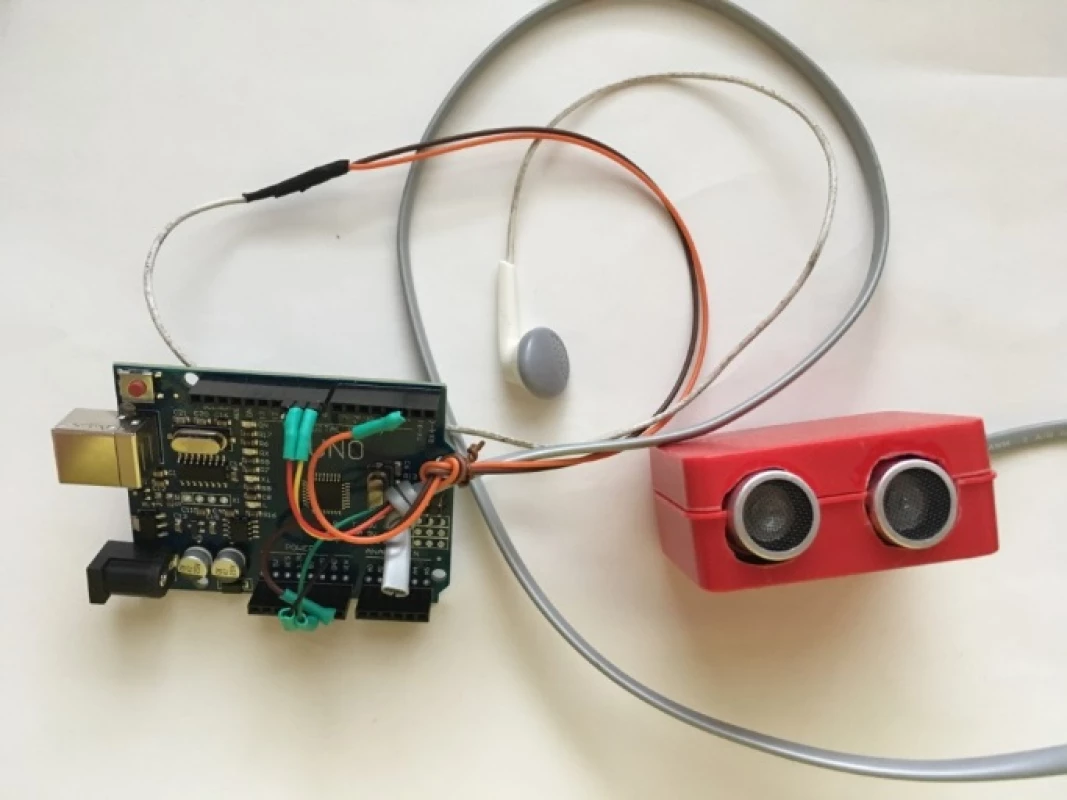

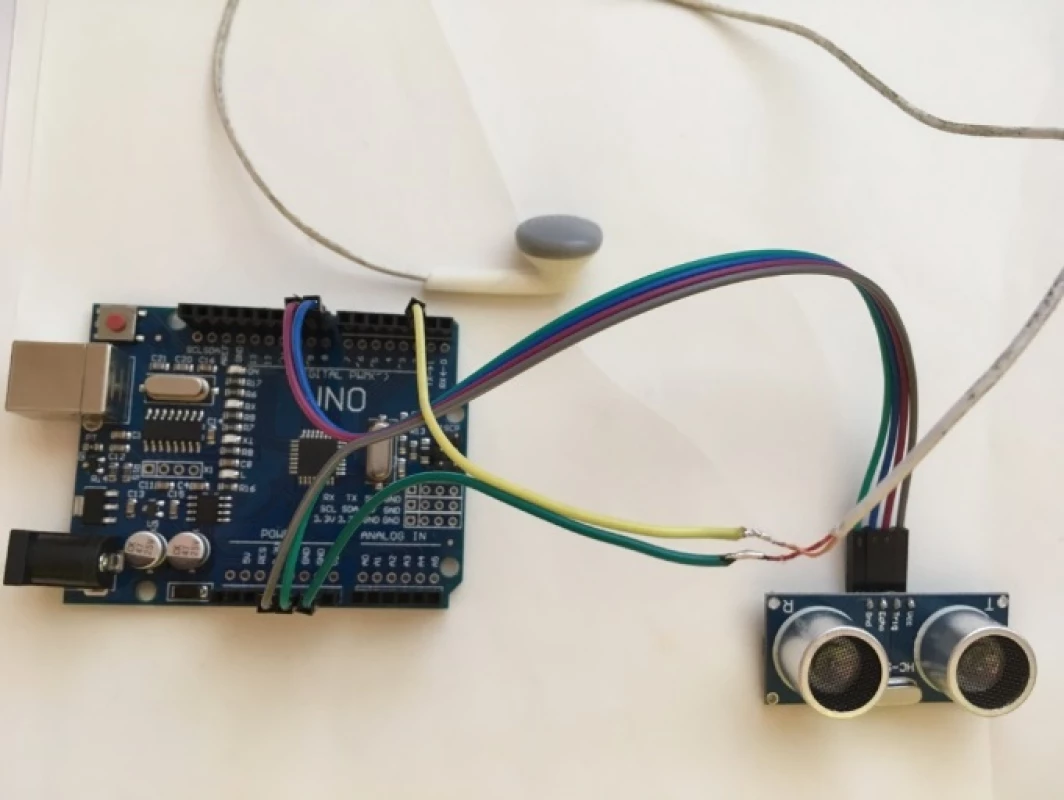

Design of electronic device support

Ultrasonic sensors work on the principle of reflecting ultrasound pulses from the object detection. From the measured time, a distance is calculated at the known ultrasound propagation velocity. The immense advan-tage of these sensors is the detection of almost any object, including transparent and shiny objects. They are not limited in surface colors and have the ability to measure bulk materials and irregular surface materials. The Ultrasonic Sensor—HC-SR04 (Yuyao Zhaohua Electric Appliance Factory, Yuyao, China) was select-ed. This ultrasonic sensor was connected to the Arduino Uno R3 platform (Arduino, New York, USA), which is the most commonly used type of board (Figure 5). The board includes the ATmega328 and classic USB processors. The board has an USB input and power input that is needed from 3.5 to 5V. The platform also includes a computer-to-speech converter, LEDs, the entire chip, digital pins, and analog inputs for measuring analogue measurements. The sensor is connected to a 4-core cable to ground, power and pins 8 and 9. To the board is connected a speaker, which is connected to the ground and pin 2. We also used the LED that is part of board in the pin 13 (Figure 5). [11, 12]

5. Connection of Arduino board and ultrasonic sensor.

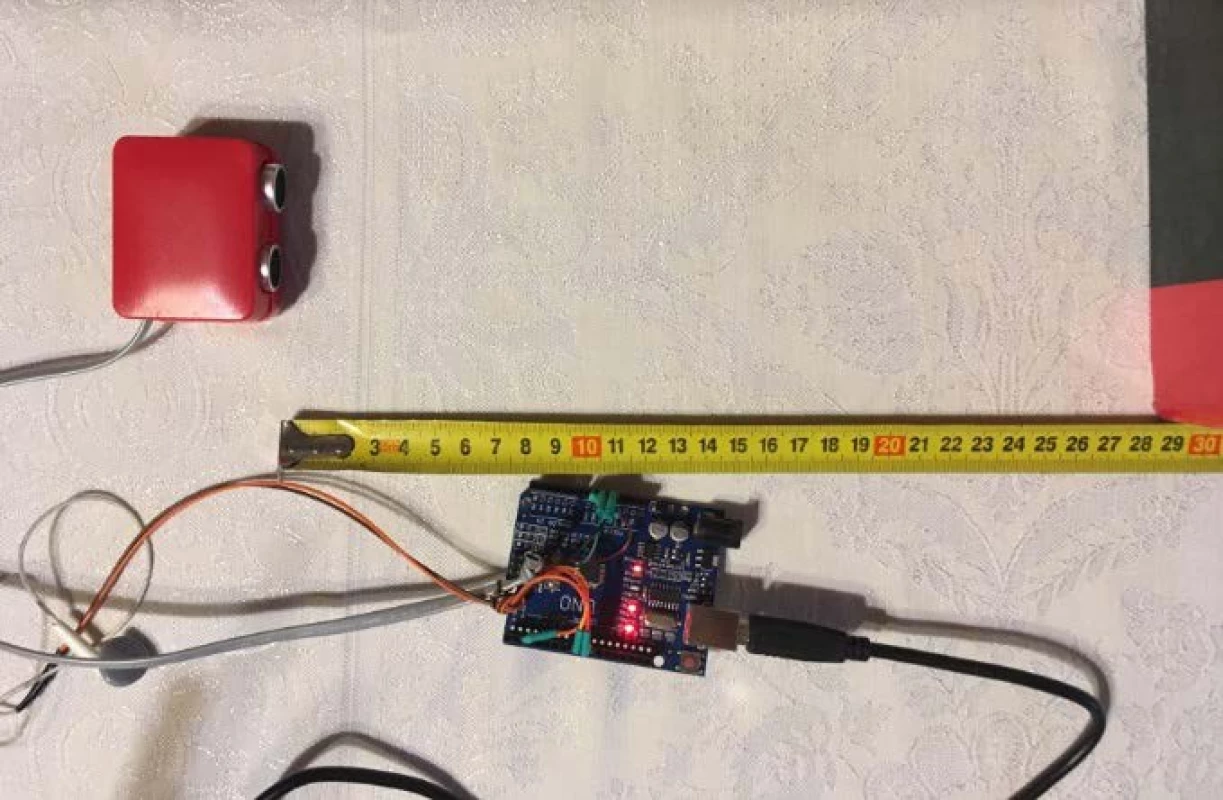

The 4-core cable supplied by the manufacturer is unfortunately too short for use. Therefore, it was neces-sary to exchange the supplied cable for a new and longer one and subsequent pins on the Arduino board and the ultrasonic sensor. The sensor has to be attached to the helmet and protected as well. It was packed in the box and attached to the helmet (Figure 6). Due to the exten-sion of the cable, it is possible to wrap the board in the packaging and then attach it to the dog harness. [13]

Figure 7 is schematically depicted as it might appear in practice. For a small dog like Jack Russell Terrier, this app is too big. A suitable solution would be to place the sensor as a part of the helmet.

For this use, a simple program was created, to initially import the New.Ping.h library, which contains the necessary commands to measure distance using an ultra-sonic sensor. It is necessary to define the location of all inputs, which in this case is only an ultrasonic sensor and outputs, ie a loudspeaker and LEDs. The program is set to scan the distance using the sonar1.ping_cm com-mand, if the distance is less than 30 cm, sends a high signal to pin2 and pin13, which means that the speaker will sound and the LED will light up. If the distance is longer than 30 cm, a low signal is sent to pin2 and pin13, which means they are off. In both options, the sensor waits for a given time and scans the surroundings again. The program works as an endless loop. As can be seen in Figure 8 at a distance is less than 30 centimeters, the signaling is illuminated and accompanied by a beep. [13]

There is no signaling at the distance the sensor records above 30 centimeters. The value of 30 centimeters is only designed and approximated. The distance is de-fined in the program and after observing the owners it is easy to change it.

The Arduino board was powered by a USB cable using a power bank. The platform is supplied with 5 V and the battery has a capacity of 2600 mAh. The attachment of the helmet sensor could not be realized because the device has a very small and rugged surface at the top. The contact surfaces of the sensor and the helmets are very small and the lacquer that the helmet is sprayed on is very glossy, so it can not be glued to it (Figure 9). The option to solve the helmet app is to modify the model so that the sensor cover is included in the helmet and would also be printed on the 3D printer, so it would be one whole. The sensor would also be inserted there.

Conclusion

The study focused on the use of sensory systems. An important part of this research was to make a tailor-made aid, and then choose the appropriate sensor type and a signaling system that will be acceptable to the dog. The impossibility of attaching the sensor in the casing to the helmet surface provides another alternative option. The solution would be if the package was ready for the sensor as part of the orthotic device. The model created by the scan would be modified to use the 3D printer to print the helmet even with the prepared sensor application surface. Such implementation would ensure a strong connection and perfect protection for the sensor—so called embedded sensorics. The sensor could also include a gyroscope that will provide signaling when it is really needed. The gyroscope is set so that the sensor is only active on the upright head. This prevents unnecessary signaling. Study brings a new look at the production of aids using non-invasive and rapid acquisition of body dimensions. Modeling in CAD software ensures complete dimensional accuracy with the possibility of virtual verification of dimensions and layout of the device. 3D printing is unmatched due to its accuracy and production speed. The future use of sensory systems gives new possibilities for rehabili-tation of both humans and animals.

Acknowledgement

This work was supported by the Slovak Research and Development Agency under the contract No. VEGA 1/0316/18 and No. VEGA 1/0971/16.

Ing. Jana Klímová

Department of Biomedical Engineering and Measuring

Faculty of Mechanical Engineering

Technical University in Košice

Letná 9, 042 00 Košice, Slovakia

E-mail: jana.klimova@tuke.sk

Phone: +421 902 310 119

Sources

References

- Bentley E, Miller PE, Murphy CJ, Schoster JV. Combined cycloablation and gonioimplantation for treatment of glaucoma in dogs: 18 Cases (1992-1998). Journal of the American Veterinary Medical Association. 1999, 215(10), 1469-1472.

- Mich P. Orthotics & prosthetics in veterinary rehabili-tation. DVM Newsmagazine [Internet]. 2011, 2011(1),

4-16 [cited 2018 May 12]. - New Blind Dog Halo by Walkin’ Pets. [Internet] [cited 2018 May 16]. Available from: https://www.handicapped pets.com/blog/new-blind-dog-halo/.

- Pavlou SZ. O&P Innovation: Links Humans with Ani-mals. O&P Business News [Internet]. 2009, 2009(1), 20-29 [cited 2018 May 12]. ISSN 1060-3220.

- Muffin’s My Blind Dog Halo, [Internet] [cited 2019 Mar 11]. Available from: https://muffinshalo.com/product/ muffins-my-blind-dog-halo.

- Artec3D, 3D Scenners [Internet] [cited 2018 May 12]. Available from: https://www.artec3d.com.

- Autodesk Meshmixer [Internet] [cited 2018 May 12]. Available from: http://www.meshmixer.com.

- Hudák R, Živčák J. Bioaditívna výroba. 1. - Košice: SjF, TU, 2015. p. 131. ISBN 978-80-89040-43-8.

- Stratasys [Internet] [cited 2018 May 12]. Available from: http://www.stratasys.com/3d-printers/fortus-380mc-450 mc.

- Živčák J, Hudák R. Biomechanizmy. 1. Košice: Sjf, TUKE, 2001, p. 343. ISBN 80-89040-06-3.

- Kohout L. Snímače polohy. Kutná Hora, 2012. Učební text VOŠ. SPŠ a JŠ Kutná Hora. [Internet] [cited 2018 May 12], Available from: http://www.edumat.cz/texty/ poloha.pdf, 27 pages.

- Ultrasonic Ranging Module HC - SR04, Elec Freaks [Internet] [cited 2018 May 12]. Available from: https:// cdn.sparkfun.com/datasheets/Sensors/Proximity/HCSR04.pdf.

- Voda Z. Průvodce světem Arduina. 2. Praha: Arduino, 2014. ISBN 978-80-87106-90-7.

Labels

Biomedicine

Article was published inThe Clinician and Technology Journal

2019 Issue 1-

All articles in this issue

- DESIGN, MANUFACTURE AND TESTING OF RABBIT IMPLANTATION STRUCTURES FOR PRECLINICAL EXAMINATIONS

- APPLICATION OF SENSORY SYSTEMS TO MOVE DOGS WITH VISUAL IMPAIRMENT

- COST ANALYSIS OF TWO TYPES OF THE LUMBAR SPINE STABILIZING SURGERY

- CERAMIC ARCHITECTURES AS MODELS FOR 3D PRINTED TISSUE ENGINEERING APPLICATIONS

- OPTIMIZATION OF ZIRCONIA INKS TO FABRICATE 3D POROUS SCAFFOLDS BY ROBOCASTING

- The Clinician and Technology Journal

- Journal archive

- Current issue

- Online only

- About the journal

Most read in this issue- OPTIMIZATION OF ZIRCONIA INKS TO FABRICATE 3D POROUS SCAFFOLDS BY ROBOCASTING

- COST ANALYSIS OF TWO TYPES OF THE LUMBAR SPINE STABILIZING SURGERY

- CERAMIC ARCHITECTURES AS MODELS FOR 3D PRINTED TISSUE ENGINEERING APPLICATIONS

- DESIGN, MANUFACTURE AND TESTING OF RABBIT IMPLANTATION STRUCTURES FOR PRECLINICAL EXAMINATIONS

Login#ADS_BOTTOM_SCRIPTS#Forgotten passwordEnter the email address that you registered with. We will send you instructions on how to set a new password.

- Career

![Halo blind dog [5].](https://www.prolekare.cz/media/cache/resolve/media_object_image_small/media/image_pdf/de7c760093b00c4824b9ac244834fe1a.jpeg)